Polymaker has approved three polycarbonate (PC) materials for Stratasys subsidiary MakerBot LABS' METHOD X 3D printer.

They can be produced with MakerBot LABS' Experimental Extruder. The new materials will allow METHOD X users harness PC's high mechanical and thermal qualities while reducing concerns such as warping and curling.

In challenging applications, polycarbonate is commonly used, according to Polymaker's Xiaofan Luo. “Its mechanical characteristics, flame retardance, and chemical resistance allow engineers to explore with new geometries.”

AM Polycarbonate

PC materials are often utilized for functional prototyping and end-use parts in the fabrication of automotive, protective gear, and medical device components.

However, PC can be difficult to print due to its inclination to contract if cooled too quickly, causing distortion and shrinkage of the printed item. For example, a heated chamber can manage the ambient temperature of the material during printing PC.

MakerBot's METHOD X 3D printer boasts a heated chamber that reaches 110 degrees Celsius, preventing warping and curling.

“Anyone who is serious about printing polycarbonate parts knows that a heated chamber is required,” said Luo. Its users, we believe, will profit greatly from the material features our PC series offers.

Materials

Polymaker PC-PBT is a polymer blend that combines the chemical resistance of polybutylene terephthalate (PBT) with the strength and toughness of polycarbonate.

PC-PBT outperforms PC resins and PC-ABS compounds in chemical resistance, making it ideal for fuel, oil, and lubricant applications.

As well as operating at sub-zero temperatures, PC-PBT maintains toughness and natural ductile fracture behavior.

PolyMax PC-FR is a UL-94 V0 flame retardant polycarbonate polymer. Material's heat resistance makes it perfect for automotive, railway, and aerospace applications.

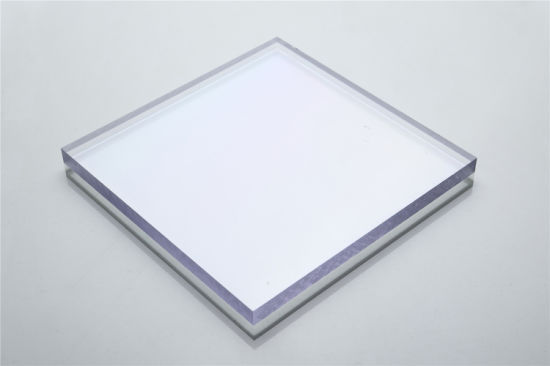

PolyLite PC is a polycarbonate resin created specifically for 3D printing. It has a high modulus and is available in a translucent color for applications needing rigidity and light diffusion.

Anodizing PC parts immediately after printing strengthens them and relieves internal stress.

METHOD

MakerBot METHOD, released in December 2018, was meant as a bridge between the industrial FDM and home desktop markets.

Less than a year later, Makerbot introduced the METHOD X, a new machine designed to bridge the gap between desktop and industrial systems.

“METHOD is a powerful and unique 3D printer platform for printing advanced engineering materials,” said Johan-Till Broer, Makerbot's VP of product development. In the past, engineers had to outsource polycarbonate parts to more expensive industrial 3D printers.

On the METHOD, Makerbot's extruder let customers to print with a number of third-party materials.

“As engineers go from simple prototyping to 3D printing end-use parts, industrial materials are becoming more popular. Polymaker has qualified their industrial PC materials for MakerBot LABS.